From roof colour to insulation, from appliances to landscaping, all the material selections made in a project form a part of the build’s overall sustainability.

Thank you for reading this post, don't forget to subscribe!Architects and Building Designers are tasked with the most important objectives; managing client expectations, design intent, – and of course budget all within site parameters and building compliance.

When it comes to achieving or exceeding a 7-star energy rating as part of the National Construction Code, few of these choices offer as much scope for variation and flexibility as the selection and application of window and door systems as a major component of the thermal envelope of the building.

Well specified windows and doors can be the difference between a thermally efficient design which comes in on budget versus an over engineered, high performing build that can confuse the most experienced specifier and possibly exceed budget – perhaps unnecessarily.

Thermally broken windows have long held the title of one of the most energy efficient solutions by offering the broadest application for use. By insulating the pathway for thermal transmission through the window frame, it’s a clever way to make the most from the durability of aluminium while reducing its conductivity – but extra components inevitably mean more assembly and a comparatively higher price tag.

So, is there a cost-efficient way to maximise energy gains, while maintaining strength and design flexibility without turning to thermally broken windows?

That’s a question both asked and answered by leading supplier of aluminium windows and doors, AWS (Architectural Window Systems). This fundamental question was asked over 10 years ago and it led to the development of a more cost effective, energy efficient solution which also offers a contemporary design aesthetic in the current market.

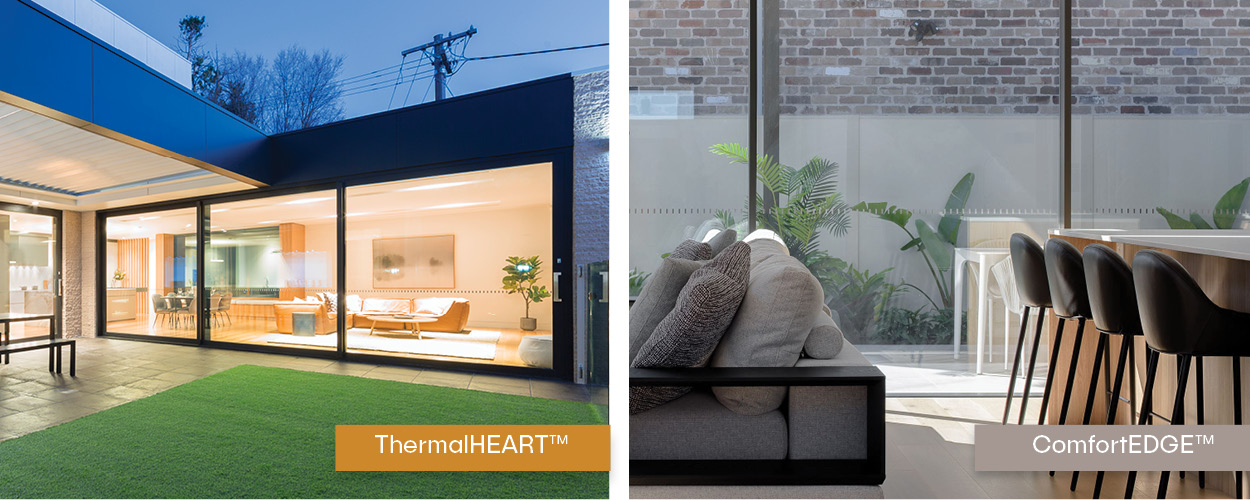

Cue ComfortEDGE™

ComfortEDGE is an elegant, double-glazed solution for residential applications that rivals the energy efficiency of thermally broken products. Its embedded frames provide a sleek design comprising fewer components than thermally broken counterparts, making it a cost-effective, wholly Australian made option for Australian projects. ComfortEDGE recognises that clever design doesn’t have to be complicated, and skilfully minimises the amount of exposed frame by embedding into the timber reveal, insulating against the environment to improve energy efficiency and thermal comfort.

ComfortEDGE truly is the perfect meeting point of form and functionality. It’s stylish and high performing, with U Values as low as 1.9 – placing you in the best position to meet 7-star energy provisions while keeping your budgeton track.

Back to weighing up your options… How will you know if ComfortEDGE is right for your project?

AWS recommends consulting your specification expert early in the design process, taking a holistic approach to build sustainably and to meet energy compliance on budget. For designers looking to harness the vast possibilities afforded by Australian designed and manufactured architectural windows, give your AWS specifier team member a call and reap the rewards. (AWS 1300 026 189)